Dental education meets Iowa innovation

Erica Teixeira was on a faculty retreat in 2018 when she noticed a solution to a problem that has plagued dental educators for years.

“As educators, we have been using plastic teeth in dental schools for educational purposes for many years,” says Teixeira, a University of Iowa College of Dentistry associate professor. “However, some of these teeth don’t offer the realistic aspect of what is happening in the mouth when decay starts and progresses into the tooth. And with naturally extracted teeth, there is a lack of standardization.”

Teixeira’s “aha” moment occurred while she was touring Protostudios in downtown Iowa City. Protostudios is a UI not-for-profit rapid-prototyping facility that serves as a one-stop shop for UI faculty, staff, students, and other inventors and entrepreneurs to ideate, develop, and create prototypes of their ideas.

“I noticed one of the 3D-printed models Chuck had displayed on his desk combining different types of materials, with clearly distinct properties, such as stiffness and hardness,” says Teixeira. “I thought there was potential to develop a better tooth model than what we have, in a more efficient, standardized manner.”

Protostudios is a University of Iowa not-for-profit prototyping workshop within the UI Office of Innovation. It was funded through the Iowa Economic Development Authority (IEDA) when it opened in 2016.

All faculty, staff, and students are able to use Protostudios to bring their ideas to life. While most of Protostudios’ projects are health care-related, any individual or private business can also take advantage of Protostudios’ services.

The main office and 3D printing hub are located at MERGE in the Pedestrian Mall in downtown Iowa City. The Anatomical and Medical Device Printing Bureau is located at University of Iowa Hospitals & Clinics, and the Machining Operations office is at Van Allen Hall.

Protostudios is responsible for prototyping the revolutionary Clubfoot Kick-Bar and USDA Soil Weather Sensors.

Teixeira was referring to Charles “Chuck” Romans, 3D design director at Protostudios. Romans, who joined the staff at its inception, has won several awards for his work on 3D prints and designs, and has worked on thousands of 3D prints, both commercial and medical.

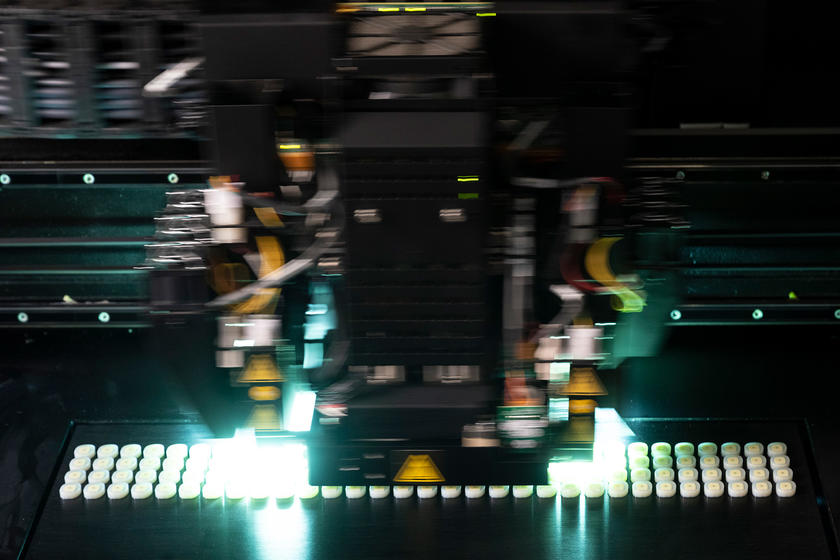

One of the many machines that Romans and the Protostudios staff use is a Stratasys J750 DAP, or digital anatomy printer, which works similarly to a common inkjet printer. This PolyJet printer can print six materials simultaneously, with about 45 different material mixes, all in one print run; instead of ink, this printer uses liquid polymers that are cured with an ultraviolet lamp and prints at resolutions of 14 microns. This allows Protostudios to make anatomy prints such as hearts and other organs for surgeons to practice on or refer to ahead of complicated surgeries.

“Erica saw this printer and asked me if I had ever done teeth,” says Romans. “I said, ‘No, but that would be an interesting challenge.’ She said they have plastic teeth that students use to practice drilling out caries. These teeth are very hard, so they break and crack easily. They don’t simulate real teeth at all. What she wanted to do was create teeth that simulate caries and are as close as you can get to a real human tooth to achieve a more realistic experience for the students.”

Dental caries are progressive tooth decay in the oral cavity that produce lactic acid that damages tooth enamel. If left untreated, it can cause irreparable damage and possibly loss of the tooth.

During the tour, Teixeira showed Natalia Restrepo-Kennedy, the Operative Dentistry I course director of the first-year predoctoral students in the Department of Operative Dentistry, to see if they could find a way to develop their own teeth using Protostudios’ services.

“When Erica showed me the possibility of doing these new teeth, I was thrilled,” says Restrepo-Kennedy. “This was a better option for educating our students.”

The process began with Teixeira sharing pictures and diagrams of teeth and providing real teeth for Romans to recreate in his computer aided design (CAD) file. Testing followed.

“We did our first round of testing in October 2018 to get some ideas,” says Romans. “Erica wanted to see if we can create real root canals, for example. We were testing the boundaries of what is possible.”

“When Erica showed me the possibility of doing these new teeth, I was thrilled. This was a better option for educating our students.”

Because these teeth are used for educational purposes, creating a consistent and realistic product for students was the top priority, and many different versions were made.

“In dentistry, understanding how it feels and how the tissue looks upon selective removal of caries is very important and a huge part of the educational process of our dental students,” says Teixeira.

And whether he wanted to or not, the process required Romans to become a pseudo-dental student while learning the intricacies of a tooth.

“There were a lot of things I had to learn when modeling the teeth,” says Romans. “There were times I thought the detail was good enough, but students are looking at it under microscopes and there are certain structures that you would only know as a dentist.”

Many iterations of the process were spent perfecting the structure and creating different layers of caries, and that required incredible precision. Romans created very fine 0.2-millimeter-thick walls within the tooth that had to be organically modeled in a particular way to ensure it printed correctly.

“You are basically assigning materials and adjusting those materials to particular bodies in the CAD model to make sure they are printed importantly,” says Romans. “The challenge was most CAD models are single parts, but this is a case where you have bodies within bodies, and you had to model those to be in the right locations. It had to be sort of a systematic approach if a change came back.”

After more than two years of collaboration, Romans and Teixeira finally got to a point where they were both satisfied with their product, named Educational Caries Teeth (ECT).

“I told Erica that I would add most of the ECT exercises to the course,” says Restrepo-Kennedy. “I contacted Chuck and told him which ones and how we needed the carious lesions. He designed each tooth, the size of the lesion, etc.”

Caries were accurately placed and diseases were simulated within the acrylic polymer, which closely resembles the enamel of a real tooth. Romans had a library of 13 different teeth he could simulate.

At Iowa, engineering grad Max Swartz found a supportive academic environment and opportunity for hands-on work in a prototyping shop. This helped him achieve his goal: landing a job in his field back home in northeast Iowa.

As course director, Restrepo-Kennedy began incorporating the ECTs into the curriculum. Last year, they used the simulated teeth for four of the five modules. The hope this fall is to add more teeth to use in all five modules.

“We currently use these teeth in many of our operative dentistry courses in a simulated environment, providing a more realistic representation of caries lesions than in the past,” says Teixeira. “We can emphasize to the students how to manage different types of lesions in a conservative manner before they perform those procedures in clinic in a patient. By being minimally invasive, we can preserve more tooth structure, and therefore increase the time a tooth lasts in the mouth.”

Now that Teixeira and Restrepo-Kennedy are comfortable with using these simulated teeth in Iowa’s classrooms, they are branching out and peer reviewing the ECTs.

“We presented our project at the American Dental Education Association (ADEA) and continue to connect with other colleagues to critically move this project forward,” says Teixeira.

The feedback they receive will help fine-tune the current teeth and allow Romans to add more to the library for the upcoming operative dentistry classes.

“I believe the ECTs have exceeded my expectations—they are more standardized, and they do not fracture. That makes a big difference when you teach 80 students who are in a learning process and are beginning to understand operative dentistry,” says Restrepo-Kennedy. “I think it gives students a better understanding of how caries management is treated in a real scenario.”

And since the word is out, the ECTs are for sale on Protostudios’ sister site, Iowamade.org, either in bulk or individual orders, for any educator or institution interested in using the product.

Throughout the 2022-23 school year, Teixeira, Restrepo-Kennedy, and Romans will continue to iterate on the ECTs; long term, the partners are considering the creation of a typodont (simulated jaw) as their next project. This work has a goal of raising the bar for simulated teeth in dental education in the country and around the world.

“We aren’t the first to try this. There are other groups around the country and at least one group in Europe that are working on things similar to what we have done, but they haven’t quite accomplished what we have,” says Romans. “What we created in simulation with the teeth, I don’t think anybody at this point has gotten to where we are.”